We are pleased to offer a variety of Bow Type Cabling Line Layouts

Model # BC-4×1800-TL

The bow cabling lines may be offered in the following configurations:

3+1, 4+1, 6+1, and 12+1 for both insulated and bare wire applications. Input cable cores may range from 8 AWG to 750 kCM (32 mm diameter).

The machines may be made for the following reel sizes: 800, 900, 1250, 1600, 1800, 2200 and 2500 mm reels.

Line 1 uses a standard overhead crane with a KALMARK-supplied REEL GRABBER ASSEMBLY.

Line 2 utlizes a KALMARK-supplied in-the-floor traversing bottom-loading SCISSOR LIFT.

Line 3 is side-loading from floor level utilizing four in-the-floor SCISSOR LIFTS. (Reel is rolled into the machine from operator’s side.)

Features (for typical 1800mm pay-off reels):

– Bows are driven at each bearing stand by HTD carbon reinforced gear belts from a common line shaft that is coupled to an in-line gear reducer and 100 HP AC vector duty motor.

– The main line shaft is braked by a pneumatic caliper disc brake. The machine is normally braked by the main driver motor with the caliper brake applied at the zero-speed condition or during emergency braking (EM).

– Bow guide roller assemblies and bearing crossing banana tube assemblies are profile machine guide rollers produced from tool steel and hardened for long life.

– The pay-off reel brakes located within each cradle are automatic electrical hysteresis brakes with constant tension follower mode.

Feature: NO OVERHEAD CRANES OR HOISTS ARE REQUIRED!

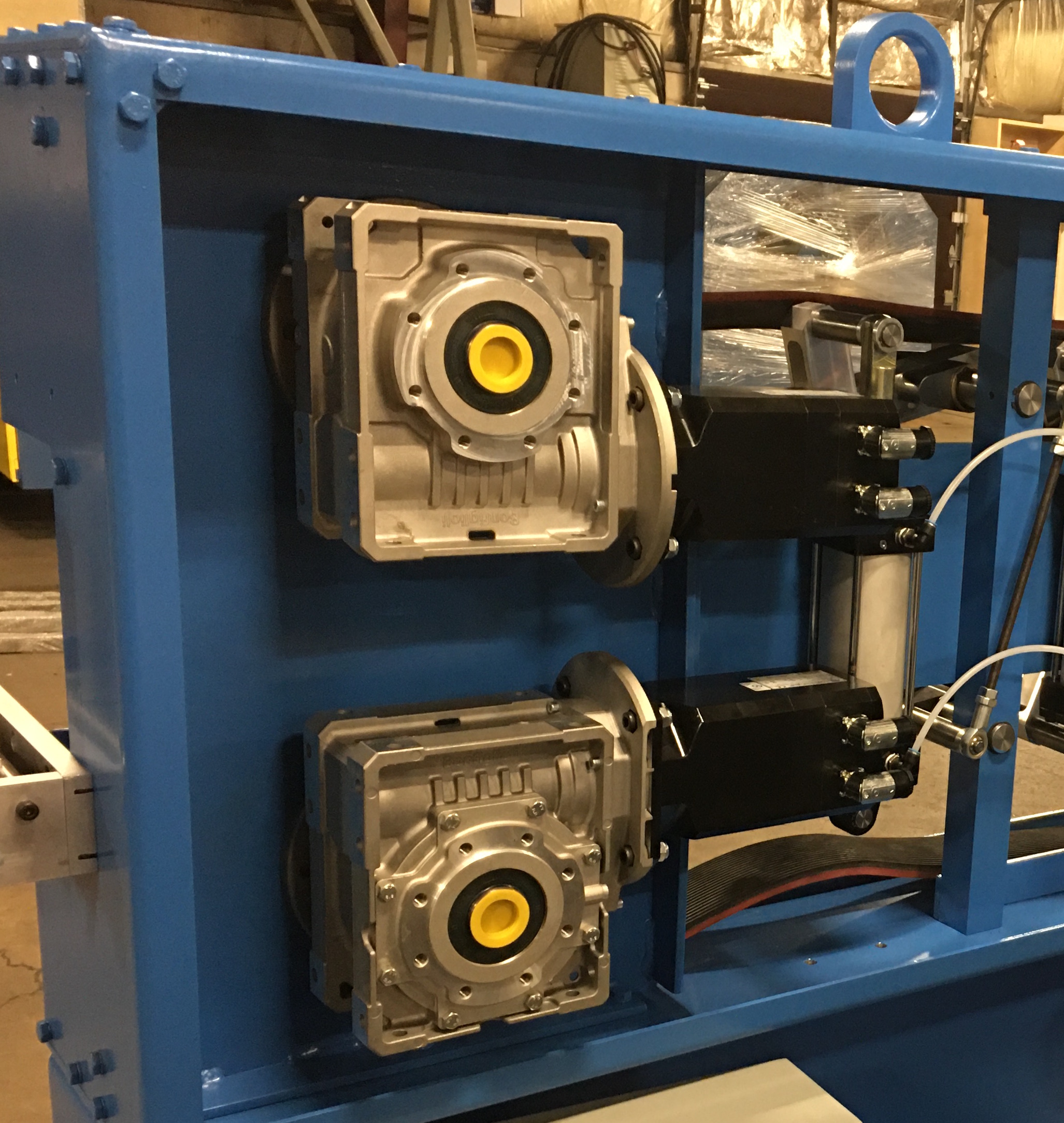

Cradle

Brake Tension Control

REEL CLAMPING—

Fail-safe spring closing with pneumatic opening side loading from floor level.

LOADING METHOD—

Reel is rolled into the machine and raised by an in the floor hydraulic platform.

(One platform for each reel cradle.)

IN-FLOOR REEL LIFTING PLATFORMS—

An in-the-floor reel-lifting platform is provided for each cabler bay. The standard scissor lift assembly is hydraulically raised and is complete with its own power pack and end stroke detection switches. Each unit is rated at 5 ton capacity. (Offered for Line 2 side-loading machine.)

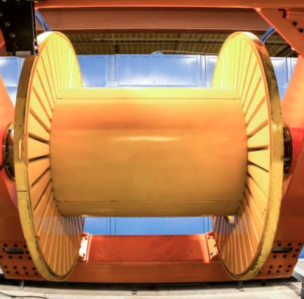

| Specifications: | (for 1800mm line): |

| Reels | 4 |

| Reel Outside Diameter | 66 to 72″ |

| Overall Width | 42″ |

| Drum Diameter | 36″ to be confirmed |

| Reel Bore | 3″ |

| Reel Weight | 5 tons |

| Pay-off Back Tension | 30 – 150 lbs |

| Maximum Bow Speed | 300 RPM |

| Cabling Direction | Left or Right Lay |

| Bow Material | Reinforced fibre glass composite |

| Machine Line Height | 36 to 74″ (configuration dependent) |

| Bow Cross Section | 3/4″ thick x 6″ wide with SS liner |

Reel Lifting Platform

Electrical

Assembly Proof Testing (Reel not shown)

REEL GRABBER ASSEMBLY—

Direct attachment to customer-supplied overhead crane hook

Unit to be manufactured for a single reel width and flange type. Customer to supply a reel drawing. GRAB assembly to be rated at 10,000 lb capacity. A floating eyelet is attached to the crane hook. 1” vertical movement is provided to interlock the control circuit by a vertical movement detection limit switch. This is to disable the reel GRAB opening circuit.

PROTECTIVE GUARDING—

Enclosure for rotating section of Bow Cabler

The rotating section of the Bow Cabler will be fully guarded. Four side-loading reel access doors are located on the operator’s side of the machine. The doors are linked together and are operated by a common pneumatic cylinder. The doors are monitored by an Allen-Bradley safety switch and wired to A/B safety relay. The guard is manually operated by a pair of push buttons located at each reel access point and is located at a safe distance from the door to prevent operator injury. The push buttons require two hands to operate.

HAUL-OFF—

The haul-off equipment may be either multi U-grooved dual-wheel capstan or linear belt-type caterpuller depending on line configuration requirements. Either system is driven by independent motor control systems following the rotation of the cabling machine.

CLOSING DIE ASSEMBLY—

This machine is supplied with a manually-adjustable closing die assembly with a stroke of 1 m. The assembly is guarded by a hinged protective guard which is also monitored by an A/B safety switch and wired to A/B safety relay. The maximum intended cable size is 3.1” OD.